The FerroCheck 2100 now analyzes grease

No solvents, no sample prep

Want to extend equipment lifetime and prevent costly failures due to wear particles? Large ferrous particles in oil and grease can often be the first indicators of a severe wear condition in rotating equipment and engines. Trending ferrous content in oil and grease allows maintenance professionals to intervene before a catastrophic failure occurs. Please watch our video below to see how the FerroCheck now works on grease sample.

Features of the FerroCheck 2000 Series include:

Accurate, Repeatable Total Ferrous Measurement

-Highly repeatable (<2 ppm)

-Large sensitivity range for oil (0-10,000 ppm)

-Wide particle size range (nm - mm)

Fast, Simple and Convenient

-Results in 30 seconds

-Portable, lightweight and battery operated

-Easy-to-use instrument for non-lab personnel

-Automated data storage and export

The FerroCheck 2100 adds the capability to measure total ferrous in grease up to 15%. Both models are now supported by ASTM standard D8120 “Standard Test Method for Ferrous Debris Quantification.”

Spectro Scientific grows patent portfolio

Four new patent grants strenghthens portfolio in key areas

Spectro Scientific has been awarded four U.S. patents covering a spectrum of analysis technologies ranging from portable instruments and software to online sensors.

Patent US9228956, “In-situ fluid analysis sensor bolt” describes an innovative online fluid sensor based on a bolt that is engineered to permit fluid to flow through and across its stem past integrated source and detector electronics. The inexpensive sensor system has no moving parts and can provide readings of TBN, TAN, water and oxidation in various lubricants without continual calibration in real time. The sensor bolt is designed to permit easy integration into machinery systems via Ethernet, serial or USB interface.

Patent US9678001, “Route-based substance analysis system and method” describes a feature of Spectro’s FluidScan® 1100 analyzer that enables service engineers to perform customized in-field oil analysis on selected subsets of assets they maintain on daily service routes. The method facilitates condition-based maintenance on the selected assets by utilizing specific information regarding both the assets and their associated lubricants to create a distinct set of system warnings and alarms for each asset.

Patent US9638669, “Portable Fuel Dilution Meter and Method” describes how Spectro’s FDM 6000 Series fuel dilution meter utilizes a special sample vial and sampling method to perform accurate and direct fuel dilution measurement quickly, using only a small sample of fluid. The method expands and increases the efficiency of the well-established surface acoustic wave technology for the assessment of fuel contamination in lubricants. It reduces the amount of sample needed to perform the analysis by nearly a factor of 100, and also eliminates sample cleanup by use of a disposable plastic vial.

Patent 9,274,041, “Particle counter and classification system”, describes a way to extend the LaserNet Fines® particle analysis technology with new capabilities to size and count ferrous particles and measure total ferrous content by weight. This technology is used in Spectro Scientific’s LaserNet 230 particle analyzer, formerly named the LaserNet Fines (LNF) Q230.

The patented technology enables the LaserNet 230 instrument to accurately size and count ferrous particles as small as 25 microns in size and measure total ferrous content below 10 ppm. These advancements distinguish LaserNet 230 as the only device on the market that performs these two measurements in one test with the highest sensitivity level. The core of the technology is two sets of magnetic coils wound with high precision to achieve the desired sensitivity level. A set of proprietary ferrous particle standards is supplied with the instrument for performance verification. The new capability makes LaserNet 230 the most comprehensive analyzer for wear particle testing in lubricants used in rotating machines within industrial and power generation plants, such as gearboxes and turbines.

Spectro Scientific Chief Technology Officer Dr. Patrick Henning said, “These patents are a reflection of Spectro Scientific's leadership and knowledge in providing comprehensive fluid analysis solutions to our customers. They range from condition-based maintenance software and portable, handheld instrumentation to online technologies. These three areas comprise the core of providing real-time solutions to the broad range of industries that rely on performance fluids."

Winner of Naval Research CNR Concept Challenge

FieldLab 58 is one of nine winners chosen from more than 200 submissions

On July 20th at the Naval Future Force Science and Technology Expo, Chief of Naval Research

.png?t=1506630016445&width=320&name=FieldLab_58_3Qtr_Right_4931b_rev_wtouchscreen_NB_2017%20(1).png)

(CNR) Rear Adm. David J. Hahn publicly announced the finalists of the CNR Concept Challenge— a historic call for innovative ideas to support the Navy and Marine Corps of the future. Spectro Scientific is pleased to be one of nine winners from more than 200 entries.

Hahn first issued the challenge in May to encourage Expo attendees to provide innovative ideas on how to keep naval ships, aircraft and personnel always at an advantage—and help Sailors and Marines either deter conflict or win decisively and return safely.

All idea submissions were reviewed by a team of subject matter experts within the Office of Naval Research (ONR), and finalists were announced during Hahn’s opening remarks at the Future Force Expo.

“The visionary ideas that we received from Challenge participants will enable us to get out in front of the rapid, ever-accelerating technology development and deployment cycle,” said Hahn. “With new advances taking place at breakneck speeds, across multiple domains, the ‘Navy and Marine Corps After Next’ truly is being created right now.”

The CNR Concept Challenge also aligns with Hahn’s new strategic direction—a Framework— for the U.S. Navy’s continuum of research and development.

Details of the CNR’s guidance were shared with Expo attendees via a new document on the way forward for naval research: “Naval Research and Development: A Framework for Accelerating to the Navy and Marine Corps after Next.” The document outlines processes for speeding new technologies from basic research into finished products, and into Sailor or Marine hands.

The winning proposal from Spectro Scientific centered around improving the performance of the Field Lab 58 portable fluid analysis lab to measure the extremely clean hydraulic fluids used in military aircraft. Specifically the proposal addresses improved measurement capabilities for particulates, water contamination and elemental contamination in hydraulic fluids.

Specifically the proposal is to add capability to this device in two areas; the IR Spectrometer module and the Particle Counter module. The work to be accomplished will focus on meeting the four test requirements defined in the AED Hydraulic Oil Fluid Sampling document, AED TTS 130751 for hydraulic fluids. These mandatory requirements are defined below.

- Particulate Analysis

- Water Analysis

- Chlorine Analysis

- Barium Analysis

Once completed this should allow the military to measure hydraulic fluids from aircraft in the field in under 10 minutes to determine if maintenance is needed. This will greatly improve readiness of the fleet.

In addition to the design challenge, Spectro Scientific has won a $9.6 million contract from the U.S. Navy to provide fluid analysis equipment and support.

Under the contract with the Naval Air Warfare Center, Aircraft Division (NAWCAD), Spectro will manufacture, test and deliver up to 69 model M-N/W SpectrOil RDE spectrometers to replace and upgrade the Navy and Marine Corp’s oil analysis programs. Technical data, logistics support documents, initial consumables, and maintenance kits/parts will be included. The atomic emission rotrode M-N/W SpectrOil spectrometer is the only oil elemental analyzer approved by the US Department of Defense (DoD) Joint Oil Analysis Program (JOAP). It is a compact, rugged, transportable and easy-to-use spectrometer designed to detect and measure metals, contaminants and additives in lubricants, hydraulic fluids and coolants. Accurate, on-site fluid analysis facilitates establishment of proactive maintenance programs and protects crucial mechanical assets from unanticipated failure.

Spectro has collaborated closely with the armed services for more than 30 years, working initially with the DoD and JOAP on early versions of SpectrOil technology. Bob Yurko, Vice President of Government Affairs, said, “The contract from NAWCAD confirms that the US Navy places a high value on the quality, reliability and support provided by Spectro fluid analysis technology as it ensures the availability and flight safety of critical aviation assets.”

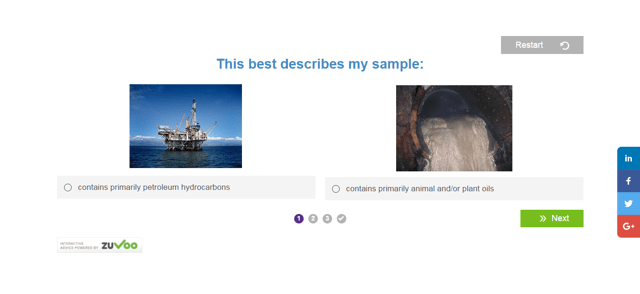

InfraCal Product Selector

Measuring FOG or oil in produced water?

Find out which InfraCal is right for you. Have you ever wondered what options you have for solvents or what InfraCal analyzer best suits your needs? We have created a new InfraCal 2 product selector to assist people in choosing the best analyzer for their needs based on sample type, solvent, and measurement accuracy required. Much like the InfraCal, it's quick and easy to use. Just answer the four simple questions and the selector will show you which InfraCal is best for your application.